LTL Blog

Lineman's Testing Laboratories of Canada

Ensuring Electrical Sa...

Ensuring the Integrity...

Tips for safety when w...

7 Benefits to Using Gr...

Electrical tape (or insulating tape) is a type of pressure-sensitive tape used to insulate electrical wires and other materials that conduct electricity. It can be made of many plastics, but vinyl is most popular, as it stretches well and provides effective and long lasting insulation. Although vinyl electrical tape has been around a long time, today you will find a variety of vinyl electrical tape available for nearly every application.

Find out which 3M vinyl tape you should be using for your applications

|

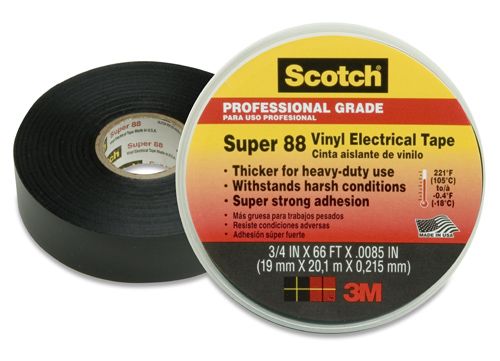

Super 88

|

Typical Application: Primary insulation for splices up to 600V Thickness: 8.5 mils Breakage Strength: 20 lbs./in. Temperature Rating: 0°F - 221°F (-18°C to 105°C) Elongation: 250% UL listed, CSA certified |

|

Vinyl Tape 35

|

Typical Application: Phase identification and marking. Harnessing. Thickness: 7 mils Breakage Strength: 17 lbs./in. Temperature Rating: 32°F to 221°F (0°C to 105°C) Elongation: 225% UL listed, CSA certified |

|

Super 33+

|

Typical Application: Primary insulation for splices up to 600V Thickness: 7 mils Breakage Strength: 15 lbs./in. Temperature Rating: 0°F - 221°F (-18°C to 105°C) Elongation: 250% UL listed, CSA certified |

Once you find the right tape for the task, remember to use the following tips for the safest and most reliable use of any 3M tape.

Taping Tips

- Apply tape with enough stretch to conform to the objects you're wrapping. Be sure to let the last couple of inches relax before tabbing it down to prevent unwinding ("flagging")

- Wrap an irregular mechanical connector, such as a split bolt, with rubber or mastic tape to pad sharp edges, before over-wrapping it with vinyl electrical tape

- Wrap cone-shaped (high voltage splices) "uphill" - that is, from the smallest to the largest point. This way you always secure the previous layer

- Keep fingers close together when tearing tape. The farther apart they are, the more the tape will stretch before it tears

Wrapping Tips

- Always use a minimum of two half-lapped layers

- The last layer should be wrapped in a more relaxed manner. Let the last wrap relax to prevent the layer from flagging

Check out our 3M tape test. We compared the elasticity of the Super 88, Super 33 and the 35+ against a competitor tape. Click this link to see the results! You can also visit our website at http://www.ltl.ca to learn about other 3M products. If you have any questions, please call your local LTL Product Specialist.

Your comment will go through an approval process and may not be visible to the public right away.