LTL Blog

Lineman's Testing Laboratories of Canada

Do what you do best...

What’s the health of your...

Stay Safe: Do Not Share...

Is There a Difference B...

6 Steps for Proper Ele...

Avoid personal liability. Take the necessary steps to minimize the risk of an arc flash or blast which may result in equipment damage and/or loss, production downtime, increased insurance premiums, but more importantly, worker injury or fatality.

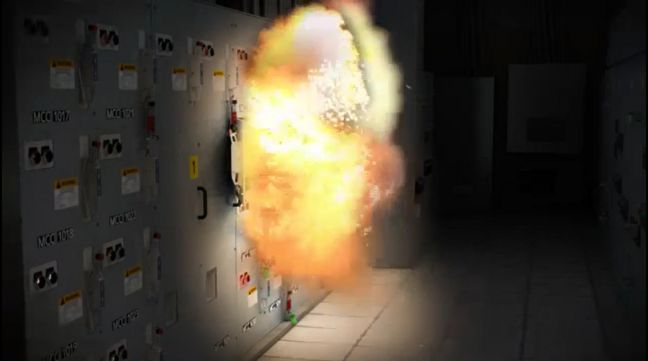

What is an Arc Flash?

An Arc Flash is a dangerous release of energy created by an electrical fault. A release such as this contains thermal energy, acoustical energy, pressure wave and debris. The temperature of an arc flash could exceed 19,426°C, capable of vaporizing metal as well as sending molten metal and a blast of plasma with extreme force. The explosion of the flash and the heat of the blast are a dangerous combination that could bring serious harm to the person on the receiving end.

Workers at risk include:

- Electrical maintenance personnel

- Trouble-shooters

- Electricians

- Linemen

- Engineers

- Site safety personnel

- Anyone exposed to energized equipment of 31 volts or more.

What causes an Arc Flash?

Electricity travels the path of least resistance. When the path of electricity is suddenly interrupted, a new pathway is created. The arc can be generated by mechanical failure, current overload, accidental contact, or human error.

Do I need to wear Personal Protective Equipment (PPE)?

There is an expectation placed on both the employer and the worker to ensure and exercise safe work practices. The Occupational Health & Safety Act (OHSA), Section 25 (2), states that the employer is to take every precaution reasonable in the circumstances for the protection of a worker, and Section 42.1 (2) states that the worker shall use rubber gloves, mats, shields and other protective equipment and procedures adequate to ensure protection from electrical shock and burns while performing the work.

Where there is risk of electrical injury, PPE is required. An Arc Flash Hazard analysis can determine the risk as well as identify what PPE should be worn.

What’s an Arc Flash Risk Assessment and do I require a study done at my plant?

An Arc Flash study (or assessment) determines the incident energy levels, boundaries, and necessary PPE required for the specific work application in your plant. The study:

- identifies arc flash hazards,

- estimates the likelihood of occurrence of injury or damage to health and the potential severity of injury or damage to health, and,

- determines if additional protective measures are required, including the use of PPE.

When estimating the probability of injury or damage occurrence, the design of the electrical equipment is taken into consideration. This includes the equipment’s overcurrent protective device, operating time, operating condition, and maintenance condition.

The CSA Z462 states that an analysis should be conducted when changes occur in the electrical distribution system that could affect the results of the analysis and is not to exceed five years to account for changes in the electrical distribution system.

LTL can help. Contact your LTL Sales Representative about our Arc Flash Safety Program, which includes:

- Arc Flash Hazard Analysis

- Supply of arc flash protective equipment

- Training

Safety strategies and proper training can minimize the likelihood of injuries and fatalities. Ensure you and your workers have the information needed to promote a safe working environment that meets all legislated requirements.

Your comment will go through an approval process and may not be visible to the public right away.