LTL Blog

Lineman's Testing Laboratories of Canada

Ensuring Electrical Sa...

Ensuring the Integrity...

Tips for safety when w...

7 Benefits to Using Gr...

Equipment damage or malfunction can cost your business thousands of dollars due to production downtime or lost time incidents. Preventative measures, such as Infrared Scanning (Infrared Thermography) should be in place in order to:

- improve plant safety

- prevent costly downtime

- reduce operating costs

- and increase equipment reliability

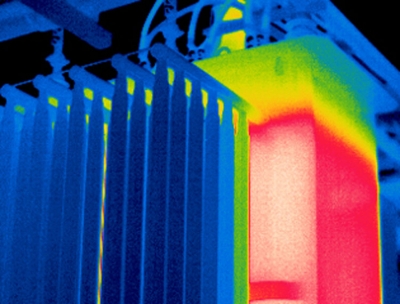

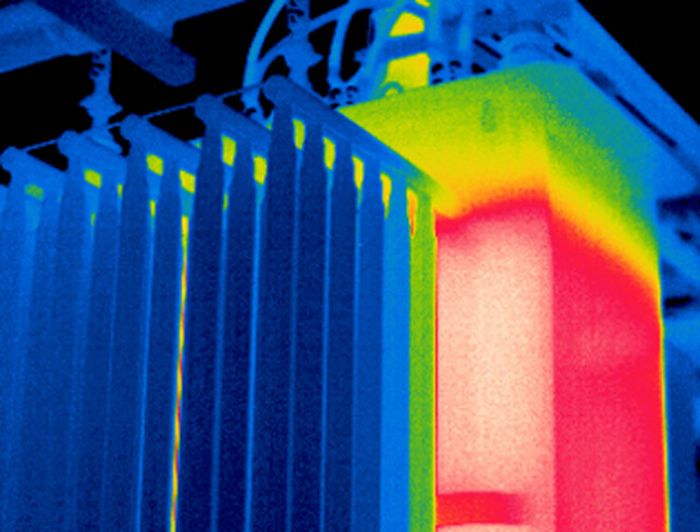

(Right: Infrared image indicating the hot spot locations in red)

It is important to remember that all Infrared Scanning programs are NOT the same. Hiring a certified Electrician who also has a license in Infrared Thermography ensures that infrared scanning has been performed by a technician who understands the effects of the hot spots captured on camera. The credentials of the technician are just as important as the Infrared Thermography report and will determine the quality and accuracy of the survey.

Lineman’s Testing Laboratories’ on-site crews include staff who are fully certified in Infrared Thermography, licensed electricians, and technicians with the qualifications and expertise to conduct full and proper inspections of all electrical equipment. Equipped and protected with the proper arc flash safety gear, our thermographers open panels as required, allowing for accurate identification of hot spot locations through thermal imaging. With a keen understanding of the effects of the hot spot, LTL technicians target the specific component requiring repair and/or replacement and identify which hot spots are critical to on-going equipment performance from those which are less immediate and can be addressed during regular annual preventative equipment maintenance.

Be proactive -- include Infrared Scanning as part of your preventative maintenance program. The infrared scan will reduce the potential for downtime, prevent operator injury and save your company unnecessary costs in the long run.

Your comment will go through an approval process and may not be visible to the public right away.