ENGINEERING SERVICES

Engineering Services

LTL’s professional engineering group works closely with our clients from start-to-finish ensuring all projects meet client requirements and are completed on-time and within budget. LTL takes into consideration municipal and provincial authority regulations and standards when preparing the design model.

Protection System Design/Upgrades

Replace existing aging protection and control equipment for added reliability and functionality

- Full design, install, and commissioning

- Protection philosophy is modeled with the existing system to match functionality

- New equipment is incorporated into existing racks or prefabricated panels for integration

- Specification and design in AutoCAD format

Protection Relay Panel Design & Fabrication

- Custom solutions

- Full design, integration, install, and commissioning

NERC Requirement Consulting

NERC (North American Electric Reliability Standards) define the reliability requirements for planning and operating the North American bulk power system and are developed using a results-based approach that focuses on performance, risk management, and entity capabilities. LTL provides the following comprehensive program:

- Site data collection

- Assessment of equipment capabilities and protection settings

- Report with recommendations for correcting equipment issues identified

- Correction/repair work , retrofit, replacement

- Test reports compliant with NERC requirements for proof of compliance

SCADA/HMI

SCADA systems (Supervisory, Control And Data Acquisition), play a vital role in the operation of Power Utilities. LTL has widespread experience with various types of communications protocols and industry standards, and provides the following:

- Design and drawings

- HMI screens

- Points list creation

- Procurement

Protection & Control Houses

- Complete substation controls in a box

- Reduce overall cost with pre-engineered integrated protection and control designs

- Industry proven components for harsh climates and environmental disasters

- Modular panel design for scalability

- Factory tested, and functionally verified with as-built drawings

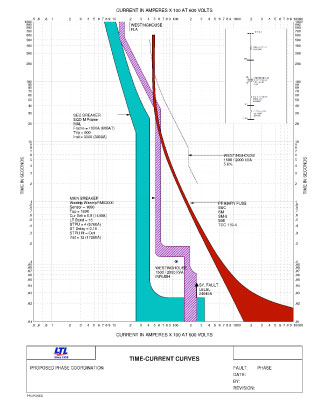

CSA Z462 Compliant Arc Flash Hazard Analyses

- Site assessment and data collection

- Short circuit and protective device coordination

- Equipment labeling

- Detailed arc flash analysis report

- Protective equipment supply and training

- Correction/repair work, retrofit, replacement

Engineering plan submissions to authorities

Co-ordination studies for substation protective devices

Substation ground grid studies and resistance testing

Power quality studies: Power factor/harmonic solutions

Troubleshooting and problem analysis

Protection & Control Relay Systems

Reliable electrical systems are the heart of your business. Lineman’s Testing Laboratories delivers high performance, cost-effective technical solutions. Our approach to engineering is to understand our clients’ needs with the vision of additional benefits and functionality from modern P&C trends.

With extensive experience in custom applications and system integration, LTL offers a turnkey solution for retrofitting or upgrading and replacing outdated protection relays.

- Engineering services extending from 600V systems to 500kV control buildings

- Integrating modern IED (Intelligent Electronic Devices) to SCADA systems

- Protection system upgrades including investigation of existing protection systems and decommissioning

- Capability with multi-vendor protection relays

- Up-to-date designs with evolving grid and cyber security requirements such as NERC PRC/CIP (North American Electric Reliability Corporation)

- Value added benefits of multi-function relaying

- Design concepts with reliability, maintenance, and flexibility in mind

- Integration services available to interface with third party installations

- Co-ordination studies and TCC graphs

At LTL, our engineering team understands the challenges of constructability when on site changes are encountered. We will work to ensure the final product goes through the proper Engineering Change Notice process to ensure quality control.

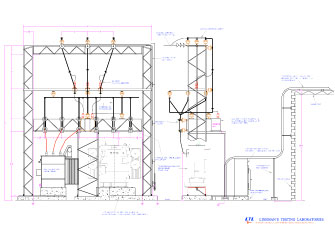

Protection & Control Panel Fabrication

The LTL team has experience in providing Protection and Control Panels to Power industries, from high voltage transmission to municipal distribution systems.

Our quality control and testing services avoid costly impact on site installation and commissioning time.

- Pre-wired panels allow for easy cost-effective integration into an existing system

- Factory acceptance testing, and witness testing services ensures a reliable product

- Relays pre-programmed with settings and fully function-tested

- CSA inspection and certification

- Connection Wiring Diagrams/Electrical Arrangement drawings can be provided as per client’s requirements

- Wiring can be compiled simply from client’s requirements, I/O lists, or major equipment shop drawings

Pre-commissioning services are also available for relay settings provided by the client. These are put through our engineering review process to identify any issues before they get to site.

Substation Controls in a Box

Integrated modular packages offer cost savings and quality, providing a pre-engineered, fully integrated, protection, control, and automation solution.

- Design-build solutions tailored to customers specific needs

- Termination racks allow for easy interface wiring on site

- Modular AC and DC power and Auxiliary Systems

- Dedicated battery bank rooms includes ventilation and automatic fan controls

- Meets or exceeds all national building codes including fire rating, temperature, wind extremes, and seismic activity

- Built to post-disaster construction specifications

INDUSTRIES

- Utilities & Industrials

- Green Power Generation (Wind/Solar)

- Co-Generation Plants

- Hydro-Electric

- Oil & Gas

Arc Flash Hazard Analysis

Lineman's Testing Laboratories' turnkey Arc Flash Safety Program: in-house electrical engineers and technicians; Canada's largest inventory of personal protective equipment and utility tools; LTL Utility Supply store stocked with thousands of industry-related products; classroom and bilingual online arc flash training.

Protecting electrical workers since 1958, Lineman's Testing Laboratories is your single source for Arc Flash safety. Our complete Arc Flash Safety Program includes a CSA Z462-compliant Arc Flash Hazard Analysis, labeling of all applicable electrical equipment, supply of all required personal protective equipment (PPE), and the option for classroom or bilingual online electrical training.

The CSA Z462 states that an arc flash analysis shall determine the arc flash protection boundary and the personal protective equipment that personnel within the arc flash boundary shall use. The Canadian Electrical Code mandates that electrical equipment shall be field-marked to warn persons of potential electrical shock and arc flash hazards. Lineman's Testing Laboratories' comprehensive arc flash studies determine potential arc flash incident energies and boundaries, shock hazard boundaries and proper personal protective equipment required for energized electrical equipment tasks for the system studied. Performed by qualified engineers and technicians, LTL's arc flash analysis includes:

- Complete engineering services

- Site assessment and data collection

- Short circuit and protective device coordination studies

- Labeling - warning labels identifying potential hazards and required safety equipment are affixed to all applicable electrical equipment

- Easy-to-read detailed arc flash analysis reports

- Supply of personal protective equipment for arc flash protection

- Training - It is imperative that workers understand how and why the required PPE will help them as well as how to properly care for and inspect this equipment to comply with legislation.

Lineman's Testing Laboratories offers both classroom Arc Flash awareness as well as bilingual online electrical training.

LTL's on-site Arc Flash awareness presentation addresses current industry standards (OHSA, CSA Z462, NFPA 70E, ASTM) and codes, as well as compliance, proper selection, care and use of proper PPE for your application.

Two program options are available with our interactive online bilingual Electrical Safety Training System (ESTS). The electrical worker course is specifically designed for the worker performing tasks within the arc flash boundary, utilizing electrical equipment, and desiring a higher level of training that is directly related to the worker's daily tasks. The non-electrical worker course is specifically designed for the individual who is exposed to, and wishes to identify, potential hazards but is not working directly on electrical apparatus.

ESTS focuses on workplace electrical safety and the application of industry accepted best practice consensus based standards to effectively manage the electrical hazards of arc flash and shock. The program applies content from the CSA Z462 Workplace Electrical Safety Standard to allow you to identify and quantify shock and arc flash hazards, while providing guidance on applying a Plan, Do, Check, Act philosophy when you have to work with energized electrical equipment. This is by far the best online electrical training available today. GO TO ONLINE ELECTRICAL TRAINING

Safety strategies and proper training can minimize the likelihood of injuries and fatalities. LTL determines the risk levels in your facility, educates your staff with respect to proper personal protective equipment selection, use and storage, and provides quality products designed to match the physical demands of your workers' jobs while ensuring their safety.

GO TO LTL'S ARC FLASH SAFETY PROGRAM